At Turnbull & Asser, we believe that true style is timeless. Our garments are not made for seasons, but for lifetimes: crafted with patience, repaired with care, and cherished across generations. We do not mass-produce; instead, we work in measured rhythm, creating shirts and ties in England, with fabrics of the finest provenance, made to last and designed with thought.

Making in England

At the heart of our making are our two Gloucester workrooms, one devoted to shirts and the other to ties. By keeping production close to home, we are able to reduce emissions while safeguarding the standards of skill that define us. Here, progress and tradition meet. A small electric vehicle ferries materials between our units; lighting is steadily replaced with LED bulbs to lessen energy use; and cardboard, plastic, and even food waste are recycled. Shipping boxes are used time and again, their journeys extended before being retired.

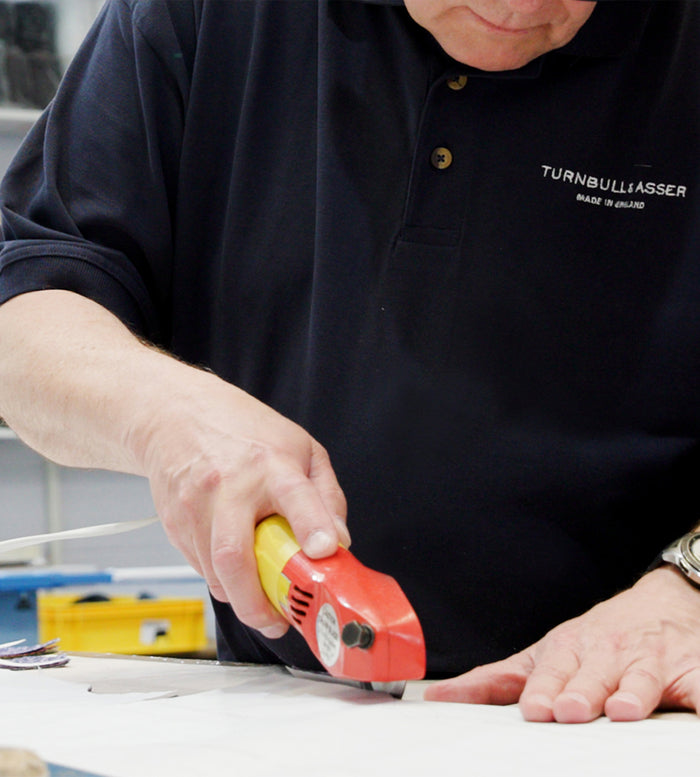

New technologies are welcomed when they bring meaningful improvements. Our automated cutting machines, for instance, carefully nest each pattern piece to reduce waste, while a newly installed fabric inspection machine limits the need for recutting, conserving valuable cloth. One third of all our shirts are custom-made, ensuring fabric is cut for purpose rather than for excess. Even the remnants are put to good use, with surplus cloth donated to a series of charities and businesses where it finds a second life within the local community.

Giving Garments a Second Life

Longevity has always been woven into the character of a Turnbull & Asser garment. To honour this promise, we offer a re-collar and re-cuff service that extends the life of much-loved shirts, often using surplus fabric from the workroom to achieve a perfect match. Our ties can be re-slipped to restore their structure, while shirts are carefully refurbished, altered, and repaired so that they may be worn with renewed pride.

Partners in Craft

We have long believed that the beauty of a garment begins with the quality of its cloth. Our fabrics are sourced from mills with whom we have built trusted relationships, many lasting decades. Wherever possible, we choose suppliers based in the United Kingdom, each selected for their commitment to sustainability, transparency, and craft.

Our buttons are made from sustainably sourced mother-of-pearl. Nothing is wasted: once the button blanks have been pressed, the remaining shell is ground into fine fertiliser. The silks used for our ties and other silk accessories are printed in England, continuing a heritage of local craftsmanship. Fabrics, meanwhile, are drawn from best-in-class mills where traditional weaving expertise meets modern innovation. These materials are then entrusted to the hands of our Gloucester seamstresses, whose artistry on hand-worked sewing machines brings each piece to life with patience and precision.

Journeys Made Considered

The journey of a garment does not end at our workrooms. We continue to refine the way it reaches its destination. Transit packaging is used time and again, its life extended before being replaced. Our packaging is both recyclable and made from 100% recycled cardboard, with vegetable-based inks. We are committed to reducing waste wherever possible and to ensuring that what protects our garments does so responsibly.

Our Makers, Our Future

Sustainability, for us, extends beyond fabric and fibre – it lives within the people who make our garments and those who will one day inherit them. Our Gloucester workrooms are home to craftsmen and women who have been with us for decades, their skills forming the backbone of our identity. We are equally committed to the generations to come, offering placements to local schools and colleges so that young people may experience first-hand the artistry, discipline, and pride of English shirtmaking.